Ratti continues its growth path with a strategic project dedicated to strengthening its weaving operations, with the goal of reinforcing internal production capacity and enhancing Italian craftsmanship.

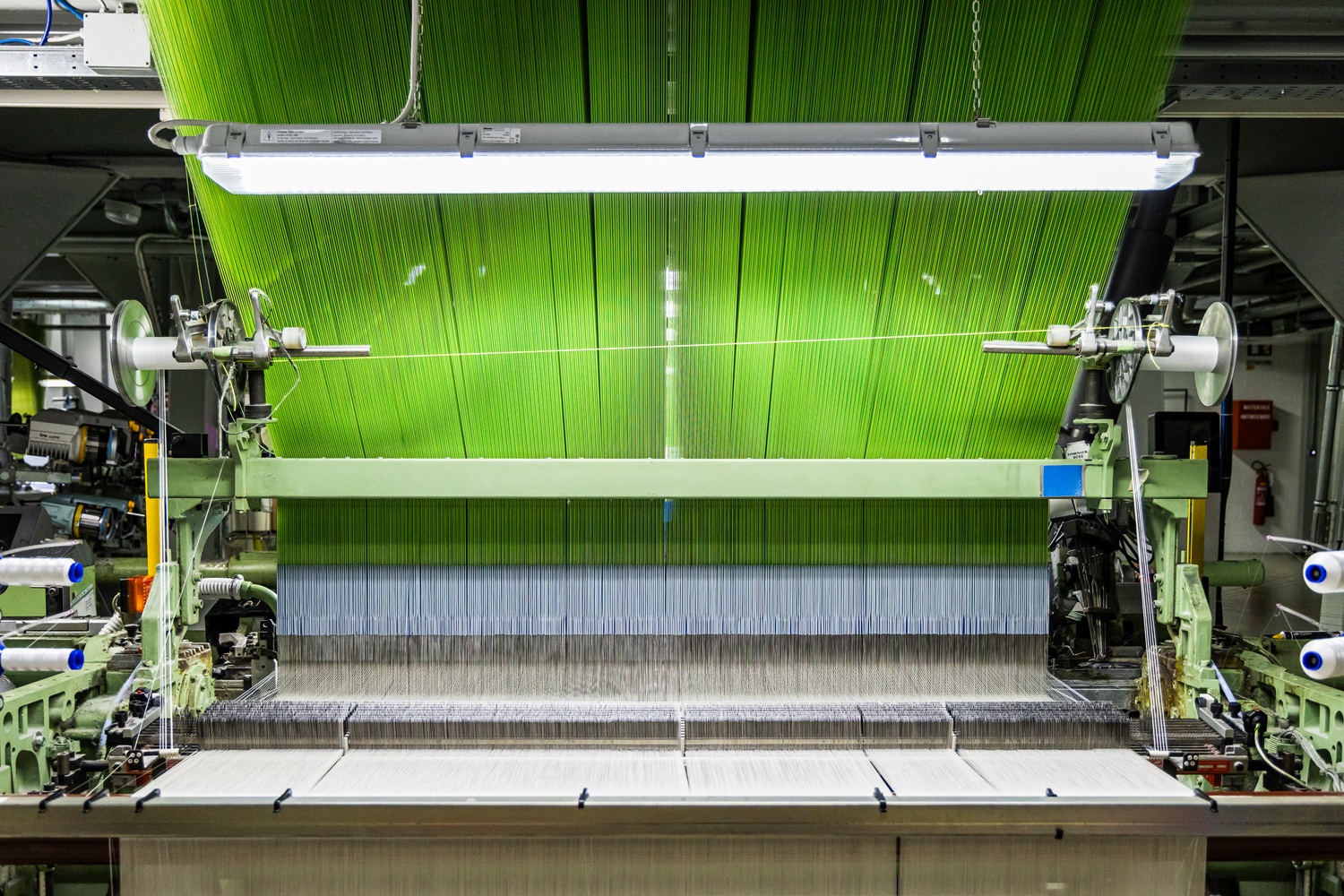

The plan includes the installation of four new looms, bringing the total to 43 operating machines over an area of 1,675 m². Thanks to this initiative, part of the production that is currently outsourced will be brought back in-house, ensuring greater control over processing and even higher quality standards.

At the same time, Ratti has launched a technological modernization program to make the entire production cycle more efficient, sustainable, and high-performing. Among the most significant upgrades is the introduction of a new steamer, which will replace one of the three currently in use. The new system improves energy efficiency and optimizes production processes, reducing consumption and enhancing the quality of fabric finishing.

Another step forward toward innovation is the acquisition of the new SKYJET machine, a cutting-edge printing technology capable of printing simultaneously on both sides of the fabric. This solution significantly increases production capacity and achieves more precise and uniform results, minimizing material waste and making the printing process more sustainable and efficient.

With these developments, Ratti strengthens its commitment to a modern and responsible textile industry—one that combines artisanal tradition and technology to meet the challenges of an ever-evolving global market.