Production

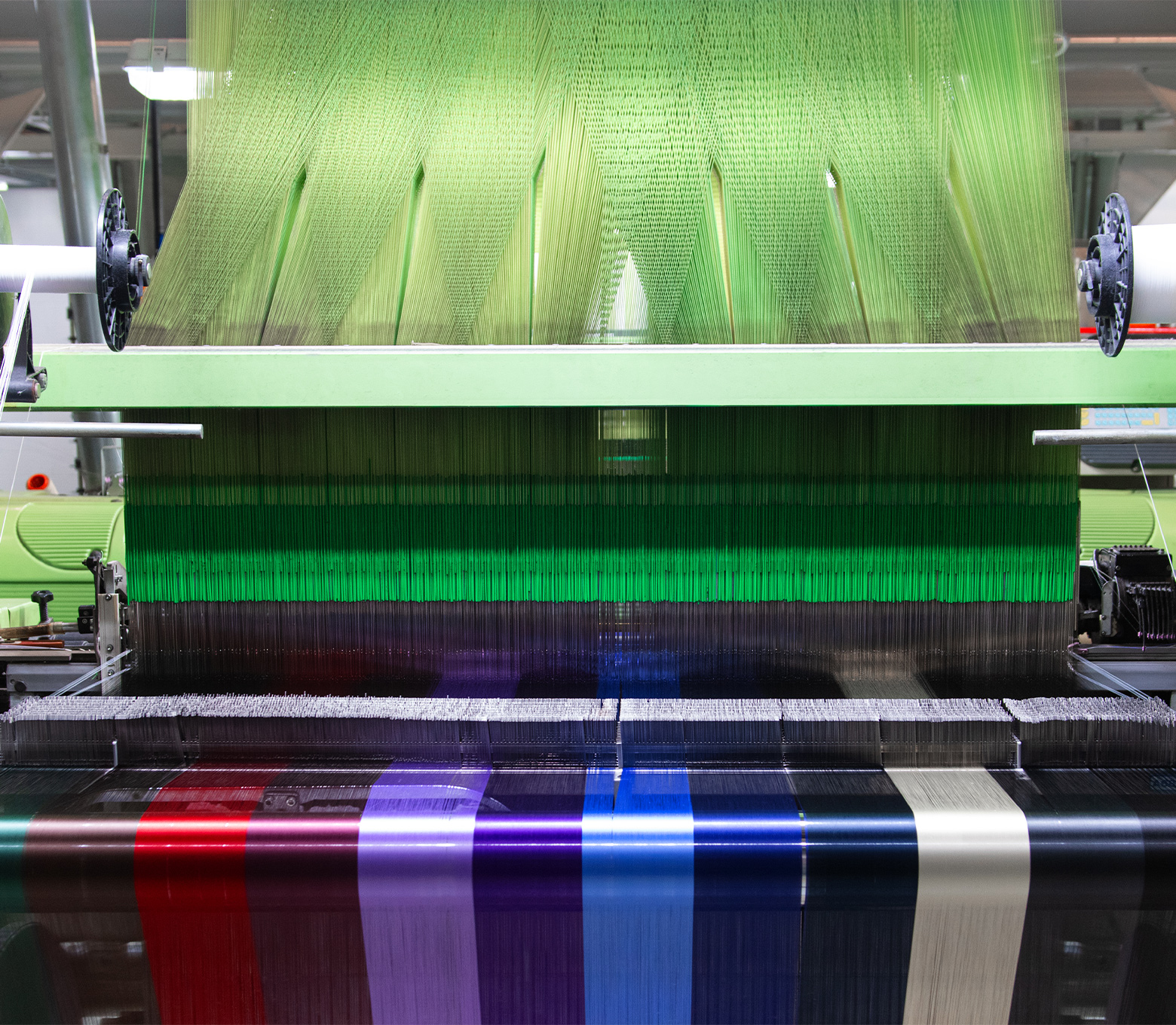

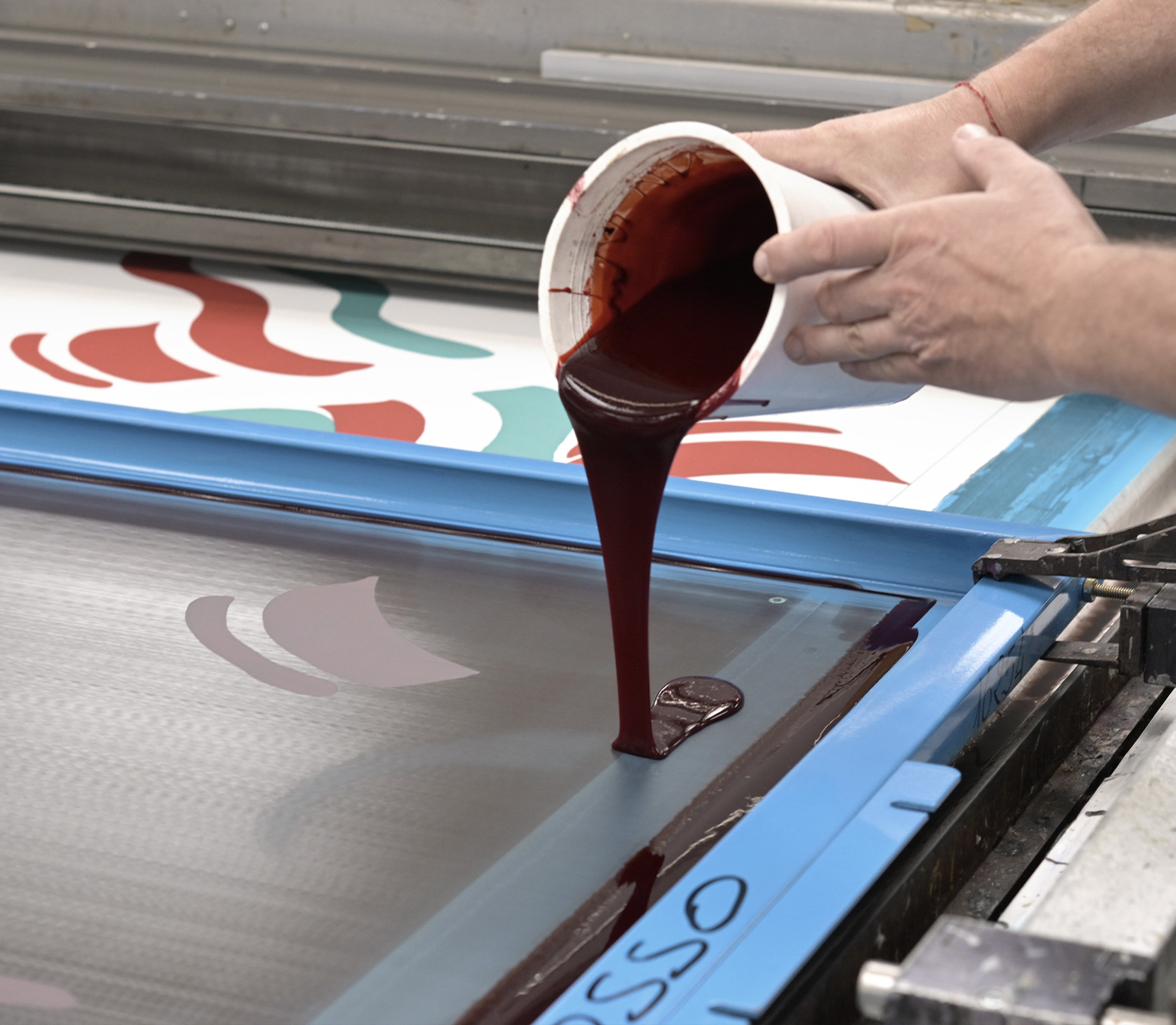

Complete control of the production process, combined with Ratti’s heritage and technological innovation, ensures customers maximum freedom of creative expression.

Ratti has a 50,000 m2 space that combines creativity, know-how and advanced technology to guarantee a complete and integrated production process,

from warping and weaving to ennobling and edging.

Ratti has a 50,000 m2 space that combines creativity, know-how and advanced technology to guarantee a complete and integrated production process, from warping and weaving to ennobling and edging.